| If your sand product isn’t meeting specifications, check these aspects of your sand plant that could be knocking your product out of spec. Understanding what’s wrong with the product Much depends on the feed but also the type of process being used to create the product(s). It is also important to understand what is wrong with the product.

Materials handling can also affect the result. Softer materials that were in spec after being washed could suffer increased breakage due to transfer points and result in a failed gradation. The first and most important thing to ask is, “What has changed?”

Here are five quick things to check: 1. FeedIn our experience, the No. 1 thing that knocks a product out of spec is the feed material. This is the first thing to check if you are out of spec. Consider the following factors:

A quick belt-cut sample and sieve analysis can answer these and a lot of other questions. Some sand plants are designed to simply wash out excess 200 mesh, so they will not address excess or lack of other fractions. In more sophisticated plants with the ability to re-blend a coarse and fine stream, getting the material back in spec could be as simple as moving the blend gate. In the most sophisticated plants, such as those using the recipe or fractionating principle, the automatic blend program will typically address these issues, adjusting on-line. But nothing will make up for a feed lacking those fractions.

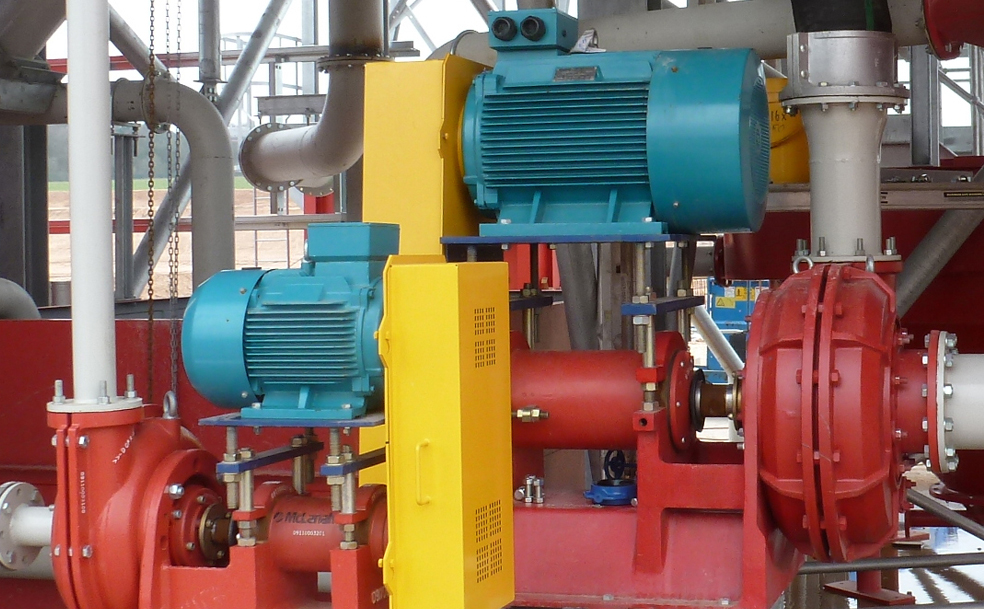

Besides the feed material, the following process and mechanical reasons can also knock the product out of spec. 2. Feed preparationNo amount of washing will work if you do not first liberate the feed materials into their discrete components. As would be the case with any mineral process, liberation is key. If you do not liberate the gold, you won’t recover it. If you do not liberate the clays up front in an aggregate plant, they will dog you downstream, contaminating every part of the process. There are multiple types of feed preparation equipment, but not all of them are designed for plastic clays should you encounter them. This part of the diagnostic process is heavily related to point No. 1 above — this is often a feed issue. Sudden changes in feed materials will play havoc with washing equipment. Log Washers and Attrition Cells are designed to handle the worst clays — but like all equipment, they can malfunction. Worn or failed components, such as paddles, are the most obvious culprits here. Check the power draw on the Attrition Cell motors. If power draw is down, then investigate internally. Also, ensure the water volume pressure is correct. 3. PumpingConfirm the water Pumps are delivering the right pressure and volume of process water to the plant.

Confirm the water source level in the ponds. Lower levels can lead to lower output with floating pier- or pontoon-type Pump mounting. Confirm the inlet pressure at the Cyclones. If Pumps are worn and not delivering the required volume, dilution water will be compromised. Cyclones and Separators™ will change in performance, allowing valuable coarser particles to report to the overflow stream or fines misreporting with the coarse. In addition, the Sump may be overflowing at the weir and coarse fractions lost to waste. Was any pipework changed? For example, changing from 10” Steel to 10” DR 11 HDPE (high-density polyethylene) can make significant differences to friction loss and lower delivered volume. 4. ClassificationIn the case of a Classifying Tank, which is typically used to address a mid-range belly often in the 30 mesh x 50 mesh fraction, an out-of-spec product could be due to:

Occasionally with changing feed, the overflow weirs need to be adjusted to increase/decrease velocity. Cyclones and Separators™ may have damaged rubber internally, which can severely compromise their performance. Check the apex diameter against original supply. The larger the diameter, the more dilute the underflow typically is — dragging unwanted fines with the water — and you may have problems controlling the Separator™ with the siphon valve. Check the condition of the underflow regulator and the siphon boot, as both affect the control and performance. Replace as necessary. 5. DewateringCheck product moisture. Increased moisture in the final product can bring undesirable fines. Is the Sand Screw or Dewatering Screen operating correctly? Higher fines content can affect the Sand Screw’s capacity and ultimate moisture. Is the Screw being starved of wash-back or rising current water due to a malfunctioning/worn water Pump? A Dewatering Screen may be malfunctioning if a vibratory motor goes out or if it has end-of-life springs/buffers. A circular or irregular motion on the screen will be evident in this case. Check the Dewatering Screen media for holes, which create a higher recirculating load and lower efficiency.

Bonus – water quality Are you actually getting good quality water back from your ponds or your Thickener? We know that excess mud can overwhelm effluent processing, including settling ponds, and it can come and go when a Pump returns mud from a malfunctioning filtration process. Preparation is key

|

|||||

-

Programs

- Contact Us

- About Us

McLanahan Corporation, headquartered in Hollidaysburg, PA, remains a world leader in the development and manufacture of aggregate process equipment and systems. Founder, James Craig McLanahan, established a focus on inventing, designing, improving and building the most efficient and rugged equipment for the most demanding industries. Today, 175 years since its founding, our reputation for these same qualities spans the globe. Now in its 6th generation of family ownership and a restructured organization, McLanahan is ready for the next century of business.

McLanahan Corporation’s Aggregate Division offers a wide range of aggregate processing equipment for sand processing, scrubbing, classifying, crushing, fines recovery and water management. They specialize in process solutions for construction aggregates such as limestone granite, sand, gravel and other similar minerals.