Eagle Iron Works Highlights the Falcon Sand Plant

For over 150 years, Eagle Iron Works has offered customers reliable, easy-to-operate equipment to handle washing and classifying applications. Eagle Iron Works is excited...

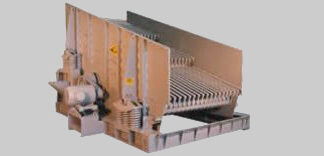

Deister BHST High-Speed Vibrating Screen Delivers High-Capacity Fines Removal

The Deister BHST high-speed vibrating screen delivers optimum separation of fine materials due to a steeper screen inclination (typically 30 degrees), effective material bed...

EIW’s Eagle+ Dewatering Screen Reduces Moisture Content in Precision Aggregate’s Concrete...

Precision Aggregate, located in Mesquite, Nev., provides high-quality construction aggregate products to the Las Vegas and northwestern Arizona marketplaces. The company operates a permanent...

McLanahan’s Complete Guide to Washing and Classifying

Naturally occurring aggregate and mineral deposits, as well as man-made industrial sands, rarely meet the specifications required of final products. These deposits often contain...

Luck Stone Sees As Low As 7% Moisture with McLanahan Fine...

Luck Stone is the largest privately held, family owned and operated producer of crushed stone, sand and gravel in the United States. Their 28...

Fines Recovery and Water Management Equipment by McLanahan

Over the past several decades, washing and classifying equipment has evolved to include a newer selection that furthers the process to include dewatering, fines...

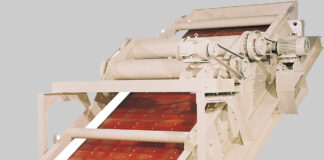

Deister Screens and Feeders

A high-capacity, two-deck, 5' x 12' inclined drum mix asphalt plant scalping screen with reversible side discharge chutes, undersized chute, stationary deck selector/bypass chute...