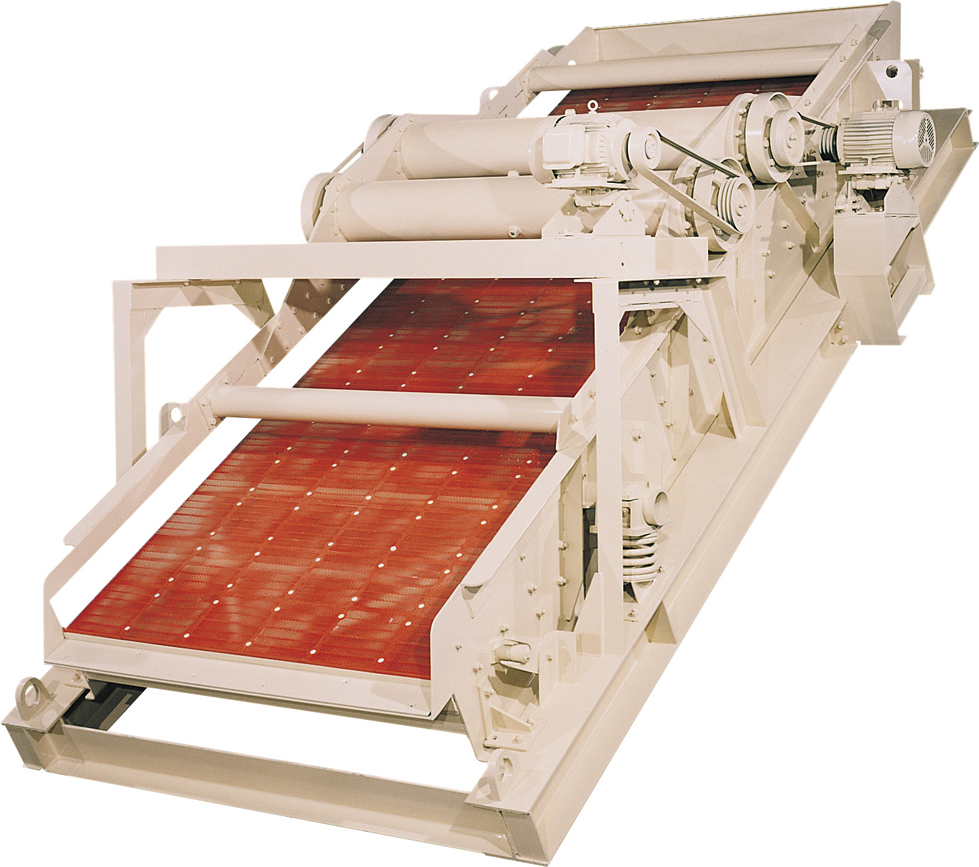

| The Deister BHST high-speed vibrating screen delivers optimum separation of fine materials due to a steeper screen inclination (typically 30 degrees), effective material bed management and higher G-force operation. Increased inclination boosts the particle travel rate, reducing the bed depth, while a higher-than-conventional speed and stroke create maximum G-forces that quickly stratify material for effective screening.

Featuring an exclusive long-life, “unitized” vibrating mechanism mounted on top of the vibrating frame, the entire vibrating system is a precision-construction, jig-assembled unit which incorporates all the advantages of a two-bearing system, and runs in a bath of oil with internal and external labyrinth seals to prevent loss of oil or contamination. A unique slingermist lubricating system makes it possible for Deister screens to operate at higher speeds and at lower operating temperatures. Deister Machine Company, Inc., is a family-owned manufacturer of all-American-made feeding, scalping and screening equipment designed to significantly increase efficiency and productivity within the crushed stone, sand and gravel, asphalt, coal, coke, slag and ore processing industries.

|

-

Programs

- Contact Us

- About Us

Deister

Always Family Owned

Always Customer-Focused

And Celebrating a Century of Service.

Deister equipment is customized to specific customer requirements and built to produce material that meets today’s rigid specifications. Designed to integrate with all other components within an operation; Deister’s reliable separating and sizing equipment is engineered to operate hour after hour, day after day, with minimum attention and maintenance.

Extremely rugged construction is the operator’s assurance of long, dependable, trouble-free, operating life from every Deister unit; while lower maintenance costs, uninterrupted production schedules and accurate sizing add up to lower costs per ton.

At Deister, service is personal and responsive as top management is personally interested in the continued profitable operation of every Deister machine.

Deister Rebuilding Services Are economic conditions limiting your ability to replace your equipment? As the original manufacturer of your equipment, we have the knowledge and experience to return your equipment to optimal operating condition. Our top-rated Deister personnel are available to visit your site to evaluate your equipment and make recommendations. Send your equipment to Deister for a detailed analysis and let our trained personnel rebuild your equipment using genuine Deister parts.

• Save money building versus buying new

• Modify or adapt equipment for other applications

• Restore equipment to “as new” condition