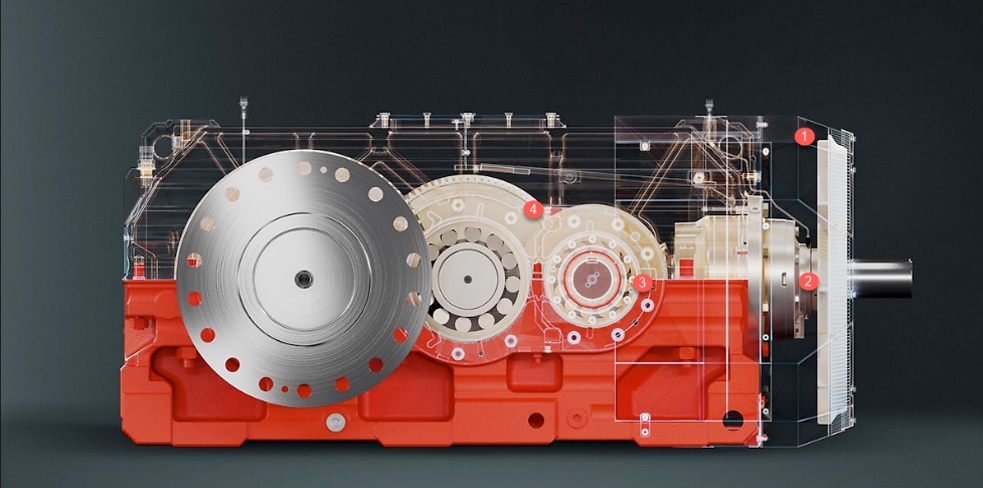

The next generation of industrial gear units has been introduced to SEW-Eurodrive’s portfolio of drive solutions. Building off the success of the X-Series helical and bevel-helical gear units, the X.e generation represents an evolutionary step in performance. Developed to the latest international standards with advanced calculations, the X.e gear units have been modeled and then validated in the harshest of conditions, both in simulated laboratories and real world applications. The results are improvements to everything a user might hope for – increased lifetime, reduced maintenance, and cooler operating temperatures – while maintaining the foot print and mounting geometry of the existing X-Series product.

The X.e generation allows a tailored fit to suit your specific drive requirements. Standardized adjustments are available in the following areas to optimize the performance most important to the user:

|

||

-

Programs

- Contact Us

- About Us

About SEW-EURODRIVE – Engineering excellence and customer responsiveness distinguish SEW-EURODRIVE, a leading manufacturer of integrated power transmission and motion control systems.

SEW-EURODRIVE solutions set the global standard for high performance and rugged reliability in the toughest operating conditions. With its global headquarters in Germany, the privately held company currently employs over 17,000 employees with a presence in 51 countries. U.S. operations include a state-of-the-art manufacturing center, six assembly plants, more than 63 technical sales offices and hundreds of distributors.