SOURCE: DSC Dredge | February 1, 2024

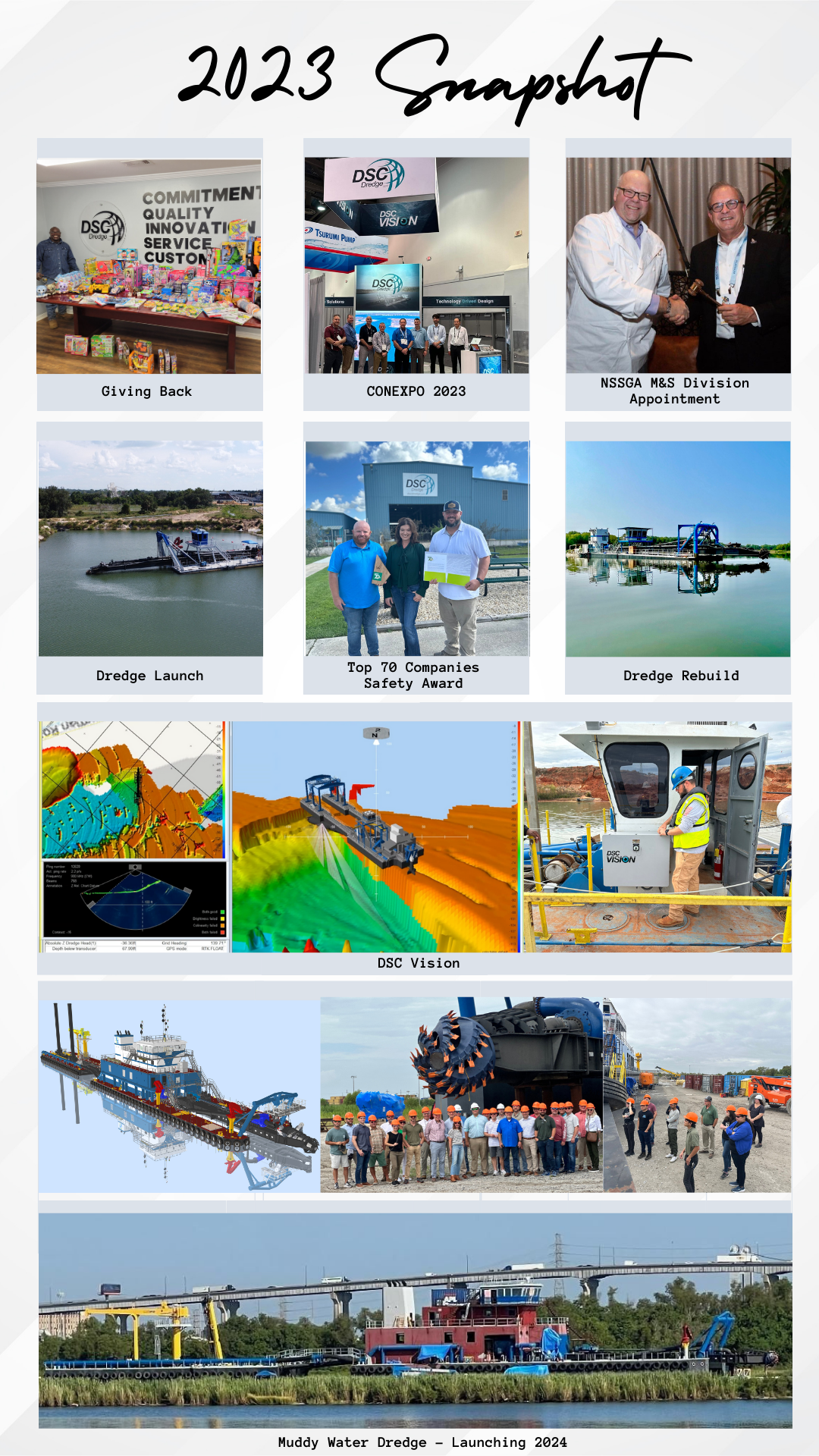

Reserve, Louisiana – For a year that started out with murmurs about a looming recession and potential layoffs, the unexpected transformation became a narrative no one predicted. From the arrival of new faces, to new client relationships, tons of support venturing into educational initiatives, external appointments and more—where does one even begin when reflecting on a year that gleamed with so much? 2023 surely proved to be yet another pivotal year filled with strategic projects and key milestones.

2023 Achievements, Milestones, and Future Ventures

At the very top of the recap, DSC introduced its Dredge Rx web application. This groundbreaking advancement not only empowered clients and future users globally but provides a seamless mobile experience over all platforms – IOS and Android. What’s even more newsworthy creating a pivotal shift was the relaunch that allowed the application to become accessible on desktop, creating new opportunities for user convenience and accessibility. The downloadable capabilities of data on desktop took the system to new levels. And it doesn’t end there. As we reflect on the successes of 2023, the depth and breadth of DSC’s capabilities shined through highlighting its diversity of projects and their locations. Notable accomplishments included the delivery of two (2) Sharks, three (3) Boosters, one (1) Marlin, a Hull replacement, and a rebuild to list a few. Additionally, our expertise was evident in the execution of projects involving a A-Frame Package Workboat, Digging Jet Package, and a rental Booster. These achievements spanned regions encompassing all cardinal points on the map, both as it relates in the U.S. and internationally.

As DSC continued to forge ahead in 2023, a new chapter unfolded with its commitment to technological advancement and training.

This brings us to the upcoming release of our Dredge Simulator. This innovative initiative promises widespread benefits for not only the dredge operator and owners but empower DSC’s own engineering team. The Dredge Simulator is not a just the ordinary VR program many offer but puts everyone in “the hot seat” allowing for a more efficient project and design. For DSC’s engineers this simulator will allow its designers to experience what an operator would thus giving them first-hand experience on what can make DSC’s engineering products more effective. For owners, it will allow them the opportunity to pretrain their operators on upcoming projects so once they are onsite, they already know what lies ahead. DSC’s dredge simulator showcases its dedication to pushing the boundaries of innovation. The final design build will be unveiled and released in February 2024.

Amidst these technological strides, the Marlin innovation takes center stage, featuring meticulously selected equipment for the single motor Marlin. Beyond its immediate impact, this innovation lays the groundwork for future designs, establishing DSC’s enduring status as an industry leader.

The success saga of DSC VISION continues to unfold as DSC successfully delivered over 29 units since its release with multiple new sales in 2023 and already on the table for 2024. As often attributed by Jason White, “imitations are the sincerest form of flattery, but innovation is the mark of the original” and while many follow, DSC continues to stay ahead, setting standards which cannot be duplicated. As DSC entered its 4th Quarter, a more ruggedized sonar unit for aggregate dredges was designed, underlining its dedication to cutting-edge solutions. William Wetta, Senior Vice President, and Chief Technology Officer, shared his insight, stating, “Over the years DSC has a proven itself as boundary pushers when it comes to technology. Our goal has and always will be to create solutions that not only meet the needs of today but propel the entire industry into a new era. With a passion for creating cutting-edge technology, our Engineering team continue to strive toward benchmarking projects that set new standards and redefine what’s possible in our field.”

On the Product Support side, our dedicated teams worked throughout the year to meet the unique needs of each of our clients. A summary of some of their projects included the onsite rebuild of a dredge with new hydraulics, a new PLC, a complete repaint, and the installation of a new cutter and service water system. Another client invested in comprehensive upgrades across their numerous fleets and locations, featuring a PLC upgrade, new cutter drive conversion, booster automation, data logging package, hydraulic function upgrade and the procurement of new tanks, PLC, and hydraulic system scheduled for installation in 2024. Amongst other accomplishments, PLC upgrades, launch and start-up support, vision installations, dredge moves and ladder hydraulic pipe installations were successfully completed for various clients. This is just a glimpse of our multi-layered achievements led by our dedicated team.

In addition to project milestones, DSC employees raised their own bars as they attended numerous training programs over the year, both internal and external, enhancing their skills and knowledge to catapult the team. The substantial growth witnessed by the company, marked by numerous new hires and internal promotions, further contributed to the dynamic and innovative culture at DSC.

Along the way DSC said farewell and celebrated the retirement of close and long-lasting friends who will never be forgotten.

2023 marked the iconic CONEXPO tradeshow which DSC’s experts were in attendance joining their industry peers but also staying abreast of the latest developments. There were also more intimate conferences such as those hosted by industry organizations such as WEDA, NSSGA, TACA, Pit & Quarry, OAIMA and IAAP to name a few. Outside of these alignments DSC received an award as one of the top 70 Safest Companies in Louisiana which spoke volumes to its unwavering dedication to maintaining a safe and secure working environment for not only its employees but also its clients. It also received recognition for being an AEM member for over 20 years.

Notwithstanding all of the above opportunities to share knowledge, DSC’s Director of Domestic Sales, Charles Johnson was appointed NSSGA M&S Division Chairman, DSC rolled out and announced its Employee of the Year Awardees (Gerald Munoz Jr. (Reserve, LA); Paul Bravo (Poplarville, MS.)).

Beyond business achievements, this year DSC employees led the way as they gave back to the community and initiated and supported food and toy drives surrounding both its locations exemplifying its dedication to corporate social responsibility and making a positive impact beyond the dredging industry. Some of the organizations that benefitted included the LOCC organization (Loving Our Community Children); Gonzales Police Department (Kids Drive); New Wine Christian Church in LaPlace; and My Brother’s Keeper in Poplarville to name a few.

As the year unfolded DSC’s HR department took the statement “investing in their future” to another level by not only hosting various college student events but welcoming them to visit its sites thus providing them with a firsthand look into the intricacies of the engineering field they are studying. This initiative allowed students to gain practical insights and experience the real-world applications of their academic pursuits. It also allowed them to visit build sites to see the theory materialized.

It is on this note that DSC officially announces that there will be opportunities for interested students looking for mentoring, on the job / internship programs, offering them guidance and support from industry experts. Stay tuned for more details as this initiative unfolds in 2024. Students interested in learning more can find DSC experts at upcoming events such as:

– LSU Career Expo 2024, February 7th, 11am – 4pm, Pete Maravich Assembly Center.

– University of Louisiana (Lafayette), Stem Career Fair, February 29th, 9am – 1pm

Also on the list are University of Mississippi Spring Stem Fair March 6th; UNO Spring Career Expo, March 8th; and Southeastern Louisiana University, March 27th to name a few.

VP & Chief Financial Officer Doy Dugan expressed his satisfaction, stating, “Thanks to the concerted efforts of the DSC team and a resilient dredging equipment market, coupled with strong results from Parts Sales, DSC achieved another commendable financial performance in 2023. Looking ahead, we are optimistic about 2024, projecting yet another great year as we ascend to new heights, driven by the collective dedication of the exceptional DSC team.”

2024 Strategic Initiatives and Exciting Events on the Horizon

As DSC enters 2024, the company is already set to build upon the foundation laid with numerous contracts secured in the latter part of 2023.

The initial quarter has already had a flurry of activity, marked by Senior Product Development and Chief Technical Officer William Wetta’s lecture at Texas A&M 53rd Dredging Engineering Short Course. This five-day training event not only showcased DSC’s commitment to knowledge-sharing but also underscores the attendance of many of our own team members eager to expand their knowledge base.

In February, DSC experts William Wetta and Charlie Johnson will be part of Pit & Quarry Roundtable & Conference Discussions, February 1st-2nd in Palm Beach Gardens, Florida. Directly following DSC will host its benchmarking event —DSC’s 3-Day Aggregate Training Short Course in the vibrant city of New Orleans. Scheduled for February 27th to 29th, 2024, this event will be include 12 Expert speakers in their fields and is supported by the esteemed National Stone Sand and Gravel Association (NSSGA).

Not far behind, March will host another highly attended event as DSC takes center stage, both attending and exhibiting at the 2024 WOA/AGG1 Tradeshow in Nashville from the 25th to the 27th March 2024 at Booth# 336. Don’t forget to map your show.

As the second quarter unfolds, DSC joins WEDA in crafting its educational course for its Annual WEDA Dredging Summit & Expo 2024, scheduled for June 24th -27th. These collaborative initiatives, coupled with the highly anticipated launch of the Muddy Water dredge which has been noted as one of the largest 24” custom dredges in the United States, set the stage for a year characterized by sustained growth, continuous innovation, and undeniable success. Stay tuned for more updates as DSC continues to shape the future of the dredging industry in 2024.

About DSC Dredge

DSC is a global leader in the dredge manufacturing industry, engineering superior customized dredging solutions to meet specific application needs, while continuing to exceed customer expectations. DSC designs and manufactures high quality, durable cutter suction and underwater pump mining dredges. At DSC Dredge, we help customers make THE RIGHT CHOICE. Quality, Innovation, Service, Commitment and Customization are key DSC attributes which explain the reasons customers choose to work with DSC. DSC Dredge operates from two manufacturing facilities located in Reserve, LA, and Poplarville, MS.

To comment on this story or for additional details click on related button above.

-

Programs

- Contact Us

- About Us

Customers who place their trust in DSC Dredge experience added benefits that go far beyond simply purchasing the right dredge. We forge a long-term relationship with you through our one-on-one attention to your unique story, working with your application details and applying our engineering expertise. We round out your experience with our ongoing operations training and timely, knowledgeable parts and service support. The hallmarks of our success are our commitment to our Customers, paired with our Designs, Customization, Quality, Value and Resale worth.

Dredge Equipment Customization

At DSC Dredge, we specialize in customizing dredging equipment to meet the exact requirements of your unique application. DSC Dredge employs the largest dredge design/engineering team among all North American and most global manufacturers. Our roots go back more than 60 years as a family-owned and -operated dredge manufacturer. And during that time, we have built hundreds of dredges. Our six standard dredge models are world-class. But our strength lies in our ability to modify or custom design any dredge to fit almost any application.

How do we do it?

- We explore all of the details of your project, such as the materials being dredged, length of flow run, depths, discharge point elevation, engine and pump preference and any other relevant information.

- You may require extreme dredging depths, deeper hulls or increased excavation power. We can make all of that happen and more.

- We involve you in every aspect of building your dredge—from specification and options to manufacture to delivery, training and maintenance.

- Upon delivery, your dredge typically will be assembled by DSC Dredge personnel and placed in service only after we run it through intensive testing.

- We then fully train your operating staff to ensure they understand the unit and its functions, so they can quickly and competently begin dredging your project.

Dredge Operation Training and Education

DSC Dredge offers numerous different and flexible training options for companies that are new DSC dredge owners. We also offer training to any company that seeks to educate its personnel on dredge operation, mine planning, dredge maintenance or maximizing dredging efficiency—even if the company operates other dredge brands.

All new DSC Dredge owners have access to a 2-day training course at DSC’s primary U.S. training facility in Reserve, Louisiana, as well as onsite operational training when the dredge is officially launched. The first day of training reviews the fundamentals of dredging, while the second day focuses on the specific operations and maintenance of the new dredge. For more information about DSC Dredge’s training options, please visit website.

Ongoing Customer Support

DSC Dredge’s Product Support Services team are the people our customers turn to throughout the entire time they own our equipment, to help keep them operating at peak efficiency and minimize downtime. The DSC Dredge product support services department offers dredge repairs and maintenance, training, retrofits, fitness surveys and dredge relocations. We also conduct onsite dredging equipment surveys, with recommendations for equipment upgrades and improvements that will increase production.