| Dings Over Head Self-Cleaning Electromagnets: Automatic and Continuous Discharge of Tramp Metal Saving Time and Labor Costs.

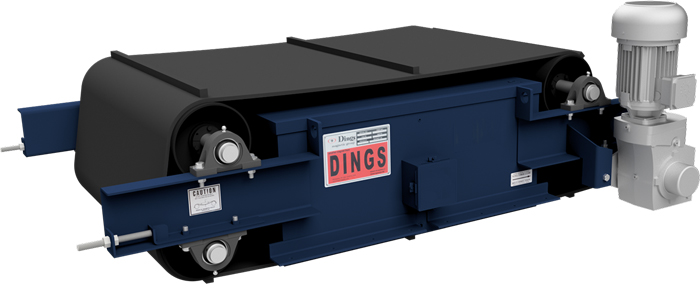

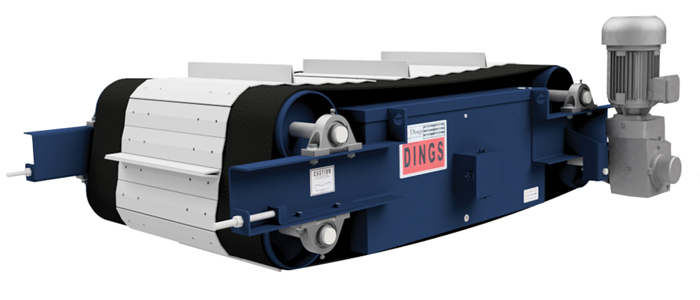

If your process risks damage to your magnetic separation equipment caused by an abundance of sharp-edged metal contaminants, Dings offers a Severe Duty model equipped with a Durabelt of stainless-steel pads and cleats. The Durabelt protects the underlying rubber belt from being pierced by sharp metal as it’s drawn up to the magnet box. The severe duty model also comes with a heavy-duty drive assembly, lagging on the drive pulley and reinforced suspension and mounting hardware.

What makes Dings co. Electromagnets better than the rest? It’s the increased performance of our unique coil design and its Industry Best 20-Year Warranty on Coil Burnout.

We encourage you to take advantage of Dings Company’s Engineering Support. When given your application details, Dings Company will provide prompt advice regarding the proper sizing, positioning and a specific description of the metal that can be separated by the magnet with accompanying performance charts. This ensures you get the correct magnet for your application’s needs. We continue our commitment to exceptional customer service by offering our expert support of all Dings magnetic equipment – Regardless of its age.

|

||

-

Programs

- Contact Us

- About Us

Since 1899 Dings Company Magnetic Group has been providing metal separation solutions to companies around the world. The company manufactures a complete line of electro and permanent overhead magnets to be positioned cross belt or in line and magnetic head pulleys for mining and aggregate applications. Dings electro magnets, self cleaning and stationary carry an industry best 20 year coil warranty.

Dings Overhead Self-Cleaning Electromagnets have deep, penetrating magnetic fields that remove metal contaminants before they can cause damage to your conveyor belts, crushers, screens, and other processing equipment. Our electromagnets are engineered for optimum performance, reliability and durability– ensuring reduction in production downtime and in repair costs and maintenance. and in repair costs and maintenance.

Dings Overhead Self-Cleaning Electromagnets have deep, penetrating magnetic fields that remove metal contaminants before they can cause damage to your conveyor belts, crushers, screens, and other processing equipment. Our electromagnets are engineered for optimum performance, reliability and durability– ensuring reduction in production downtime and in repair costs and maintenance. and in repair costs and maintenance. Dings’ Self-Cleaning Electromagnet comes equipped with a multi-ply rubber self-cleaning belt with 1-inch hot vulcanized cleats. This belt continuously travels across the face of the magnet, automatically discharging tramp iron. This design eliminates the time and labor costs associated with manually removing tramp metal from a stationary magnet.

Dings’ Self-Cleaning Electromagnet comes equipped with a multi-ply rubber self-cleaning belt with 1-inch hot vulcanized cleats. This belt continuously travels across the face of the magnet, automatically discharging tramp iron. This design eliminates the time and labor costs associated with manually removing tramp metal from a stationary magnet.

Detail of Dings Dura Belt steel pads and cleats.

Detail of Dings Dura Belt steel pads and cleats.