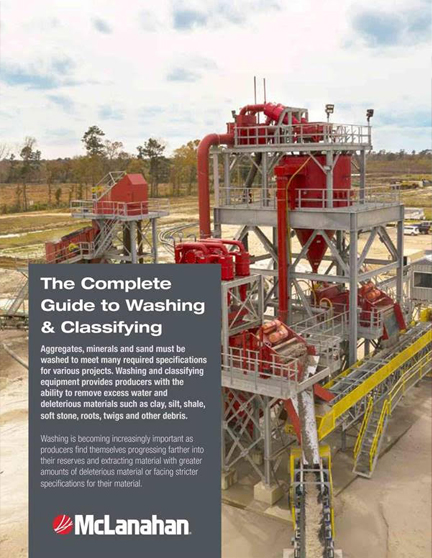

| Naturally occurring aggregate and mineral deposits, as well as man-made industrial sands, rarely meet the specifications required of final products. These deposits often contain deleterious material such as clay, silt, twigs and other debris that can decrease the quality, efficiency and durability of the final products if not removed. Crushed sands often contain an excess of harmful fines that can throw the end product out of spec. Removing these fines and deleterious material is key to producing the high-quality aggregates and minerals that are necessary for their various end uses. This is why washing is essential for many aggregate and mineral production processes.

Removing these fines and deleterious material is key to producing the high-quality aggregates and minerals that are necessary for their various end uses. This is why washing is essential for many aggregate and mineral production processes.

|

-

Programs

- Contact Us

- About Us

McLanahan Corporation, headquartered in Hollidaysburg, PA, remains a world leader in the development and manufacture of aggregate process equipment and systems. Founder, James Craig McLanahan, established a focus on inventing, designing, improving and building the most efficient and rugged equipment for the most demanding industries. Today, 175 years since its founding, our reputation for these same qualities spans the globe. Now in its 6th generation of family ownership and a restructured organization, McLanahan is ready for the next century of business.

McLanahan Corporation’s Aggregate Division offers a wide range of aggregate processing equipment for sand processing, scrubbing, classifying, crushing, fines recovery and water management. They specialize in process solutions for construction aggregates such as limestone granite, sand, gravel and other similar minerals.