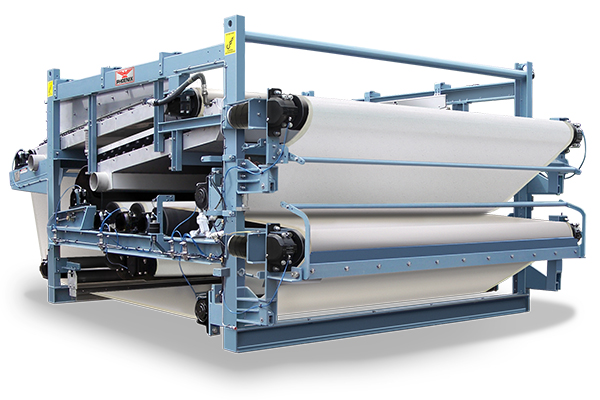

| The PHOENIX Belt Filter Press delivers exceptional liquid-solid separation for industries like mineral washing, wastewater treatment, and pulp and paper production. Designed to handle large slurry volumes, it transforms pumpable slurries into solid, stackable cakes, enhancing efficiency and reducing operational costs. Backed by 30+ years of innovation, PHOENIX offers tailored configurations to meet diverse needs. The rugged WX model features a fully welded mainframe and advanced corrosion protection, while the compact LC model is perfect for smaller applications. Trusted across industries, PHOENIX Belt Filter Presses deliver consistent performance and durability for superior dewatering results.

Users like to install the powerful IMI Magnetic Separation Pulleys as head pulleys in conveyor system applications. As the belt conveyed product travels over the magnetic head pulley, any ferrous metal that is mixed in with the product is attracted and held to the face of the belt and carried to the underside of the conveyor. After the metal passes out of the magnetic field, it is released and discharged into a chute or bin for disposal. The cleaned product, which is unaffected by the magnetic field, is discharged normally over the pulley away from the tramp metal. PHOENIX Belt Filter Press Features/Benefits:

Applications for the PHOENIX Belt Filter Press include:

Website Link: https://dewater.com/belt-filter-press/

|

|

-

Programs

- Contact Us

- About Us

Since 1984, PHOENIX Process Equipment has been providing custom system solutions and equipment for sand & minerals classification; fines slurry separation, thickening & dewatering; separating lightweight, deleterious materials from aggregate & minerals products; and for dewatering tailings slurries from aggregate & mineral processing plants.

In addition to a broad line of equipment, PHOENIX provides process evaluation, sampling, lab services, pilot plants, flow sheet development, facility design, installation & service, field execution & commissioning and parts inventory to support application equipment.

PHOENIX system solutions and equipment technologies include: Attrition Scrubbers Hindered Settling Classifiers Bucket Wheels Logwashers High-Rate Thickeners Paste Thickeners Belt Filter Presses Recessed Chamber & Membrane Filter Presses

WE’RE ALL ABOUT THE PROCESS.

Heavy-duty all-welded main frame assures component alignment.

Heavy-duty all-welded main frame assures component alignment.