Name: Steve Tanzilo

Phone: 541-549-1359 |

|

Dings Overhead Stationary Electromagnet

If tramp metal is rare in your process but must be removed… Sometimes Simpler is Better. Dings Overhead Stationary Electromagnets protect your conveyors, crushers, screens and other valuable processing equipment from damage caused by tramp metal. The stationary model, with no moving parts, is virtually maintenance-free. All you need to do is periodically check the cooling oil. The stationary model has no self-cleaning belt to sag, allowing for a lower suspension height. As a decrease in suspension height comes with an increase in performance, it may make the use of a smaller, more economical magnet possible.

The feature that makes Dings electromagnets the best choice for your application is our unique coil design of anodized aluminum strap instead of insulated wires. This coil design produces a stronger, deeper and more uniform magnetic field than the others and doesn’t require an external oil tank or pipes. Dings Company stands behind the quality of our electromagnetic coil design with an industry best 20-year warranty on coil burnout.

Dings Overhead Self-Cleaning Electromagnets

If ferrous metal is prevalent in your application, Dings self-cleaning electromagnets are an optimal choice. Dings self-cleaning magnets uses a multi-ply rubber belt with 1-inch vulcanized cleats that travels across the magnet’s face, automatically discharging ferrous material, saving time and labor costs. In applications where, sharp tramp metal is common that can damage the self-cleaning belt, an optional armor-clad Dings “Dura Belt” of stainless-steel pads and cleats is also available.

Just like the Stationary model, the feature that makes Dings electromagnets the best choice for your application is their unique coil design of anodized aluminum strap instead of insulated wires. This coil design produces a stronger, deeper and more uniform magnetic field than the others and doesn’t require an external oil tank or pipes. Dings Company stands behind the quality of their electromagnetic coil design with an industry best 20-year warranty on coil burnout.

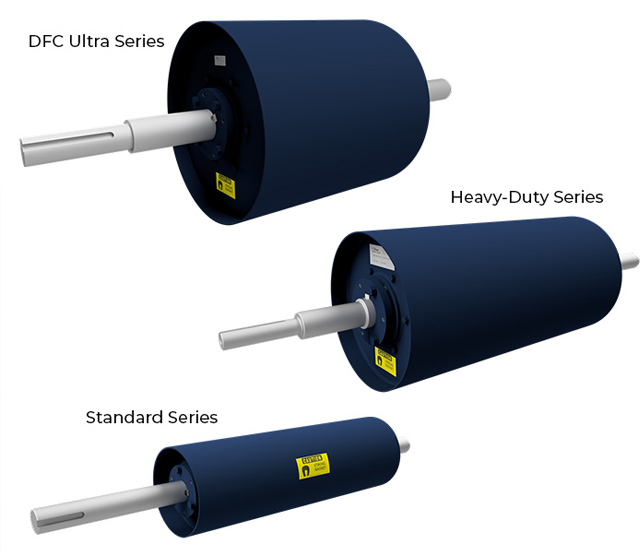

Dings Magnetic Head Pulleys

Dings Magnetic Head Pulleys are non-electric, self-cleaning magnetic separators. They operate as head pulleys on conveyors to separate tramp iron from materials conveyed in bulk form. They are designed for machinery protection and product purification. The Dings head pulley’s magnetism is produced by an internal permanent magnet assembly that is enclosed within a nonmagnetic stainless-steel shell. Dings manufactures pulleys in three different field strength series; standard, heavy-duty, and DFC Ultra. All magnetic head pulleys come shipped ready to install!

SurroundScan Protector Series Metal Detectors

by Advanced Detection Systems, a Dings co. Magnetic Group Sister Company

Dings Co. Magnetic Group’s sister company, Advanced Detection Systems, engineers and manufactures metal detection systems. The Protector Series detects ferrous, non-ferrous or stainless steel that made it past your magnetic separators. Metal detectors, when used with proper magnetic separation, complete the ferrous metal protection process. Or if metal is very rare in your process, a metal detector can be an economical and easy to install alternative to an overhead magnet.

The Protector series metal detector will detect metal, alert workers and shut down equipment before it can be damaged. The Protector’s steel construction and NEMA 4 electronics enclosure is designed for outdoor use and the removable end plate facilitates easy installation into existing processing lines. Protector series metal detectors are available as complete systems with splice sensors and metal markers.

Follow us on:

|