| Engineered for Speed. Designed for Safety. Built for Efficiency.

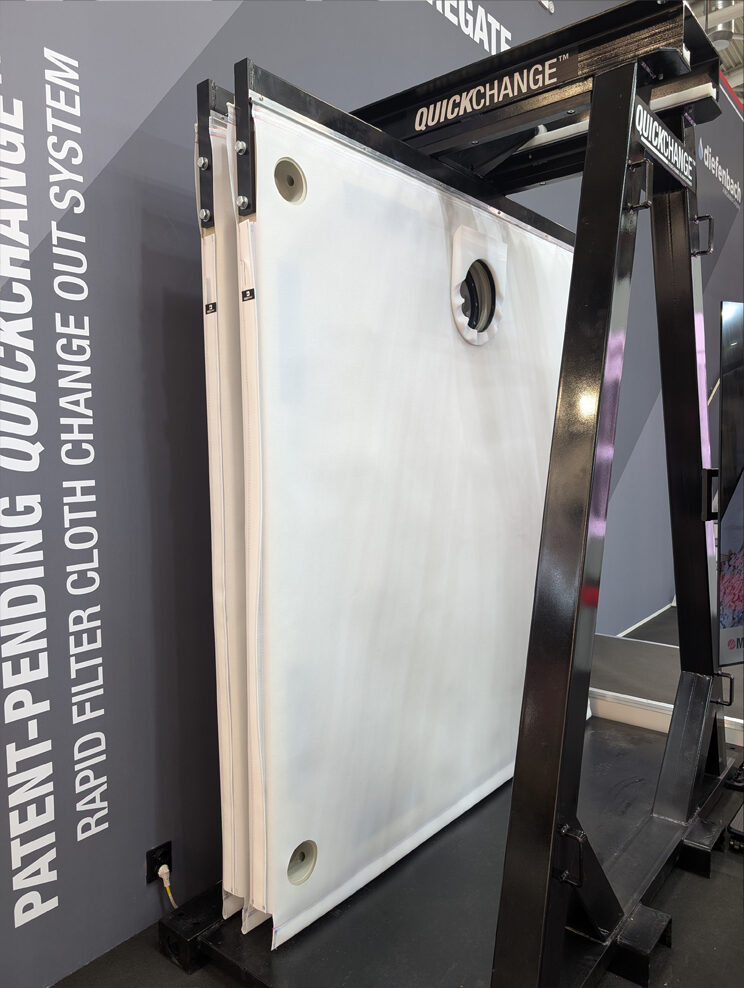

McLanahan Corporation, in partnership with its sister company Diefenbach, proudly introduces the QUICKCHANGE™ Rapid Filter Cloth Changeout System—a patents-pending innovation set to redefine filter press maintenance across industries. Engineered with speed, simplicity and safety in mind, the QUICKCHANGE™ reduces downtime, mitigates safety risks and delivers measurable cost savings through an intuitive design that transforms how filter cloths are replaced and filter plates inspected.

Launched in 2025, the system is available through McLanahan, Diefenbach and Eagle Iron Works. Innovation That Moves Operations Forward

This system allows filter cloths to glide effortlessly in and out for changeouts, eliminating the need for cranes, overhead lifting systems or labor-intensive manual work. Engineered for Safety and Simplicity in Mind Built for Durability and Lower Operating Costs Ideal for Multiple Industries To schedule a demo or learn more, visit: https://mclanahan.com/

|

|

-

Programs

- Contact Us

- About Us

McLanahan Corporation, headquartered in Hollidaysburg, PA, remains a world leader in the development and manufacture of aggregate process equipment and systems. Founder, James Craig McLanahan, established a focus on inventing, designing, improving and building the most efficient and rugged equipment for the most demanding industries. Today, 175 years since its founding, our reputation for these same qualities spans the globe. Now in its 6th generation of family ownership and a restructured organization, McLanahan is ready for the next century of business.

McLanahan Corporation’s Aggregate Division offers a wide range of aggregate processing equipment for sand processing, scrubbing, classifying, crushing, fines recovery and water management. They specialize in process solutions for construction aggregates such as limestone granite, sand, gravel and other similar minerals.