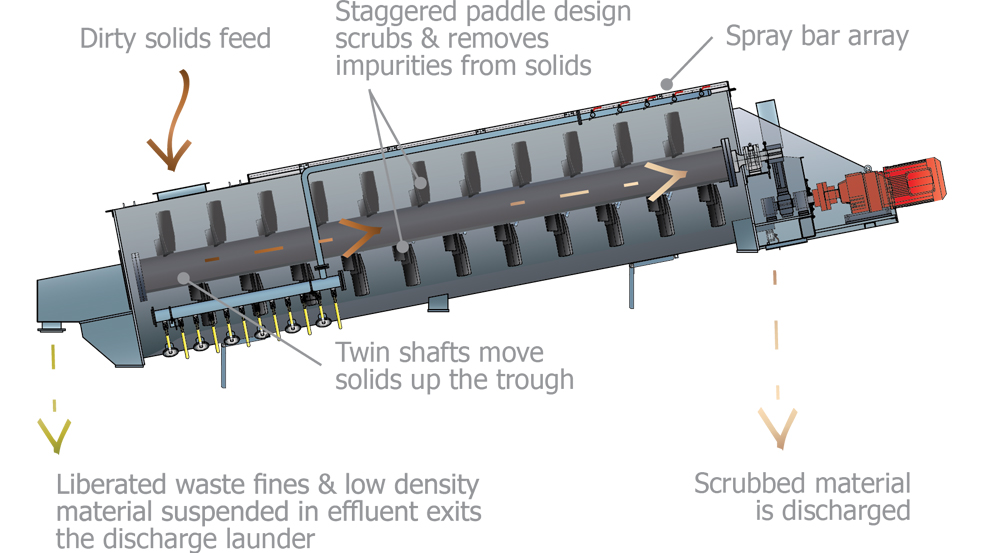

| The PHOENIX/KISA Twin Shaft Logwasher is an essential component of a wash plant’s aggregate washing equipment. The Logwasher removes dirt, loam, clay contaminants, and other deleterious materials from raw aggregate materials such as dirty limestone, dolomite, and high silica content gravel. Logwashers have the capabilities of handling large rock and high tonnage feed capacities up to 700 STPH. The rugged drives, shafts, and paddles are ideal for a variety of applications requiring severe scrubbing and de-agglomeration. Impressively, these Logwashers can process up to 700 Short Tons Per Hour with rocks up to 12” and provide low water consumption as low as 1.0 GPM per ton of feed. Furthermore, optional upflow nozzles can be added to enhance wood/organic removal.

LOGWASHER PROCESS: Water is added by spray-bar arrays at the top end of the trough, while solid material advances up the inclined trough by paddle action. Force-synchronized, interlocked counterrotating twin shafts with staggered paddles create intense paddle-rock & rock-on-rock shear action to remove the impurities from the material. Scrubbed material dumps from the discharge chute at the top end of the trough and waste liberated fines & low density suspended matter exit through the discharge launders.

|

|||||

-

Programs

- Contact Us

- About Us

Since 1984, PHOENIX Process Equipment has been providing custom system solutions and equipment for sand & minerals classification; fines slurry separation, thickening & dewatering; separating lightweight, deleterious materials from aggregate & minerals products; and for dewatering tailings slurries from aggregate & mineral processing plants.

In addition to a broad line of equipment, PHOENIX provides process evaluation, sampling, lab services, pilot plants, flow sheet development, facility design, installation & service, field execution & commissioning and parts inventory to support application equipment.

PHOENIX system solutions and equipment technologies include: Attrition Scrubbers Hindered Settling Classifiers Bucket Wheels Logwashers High-Rate Thickeners Paste Thickeners Belt Filter Presses Recessed Chamber & Membrane Filter Presses

WE’RE ALL ABOUT THE PROCESS.

PHOENIX/KISA Logwasher operating on site

PHOENIX/KISA Logwasher operating on site Dirty feed being conveyed to Logwasher

Dirty feed being conveyed to Logwasher