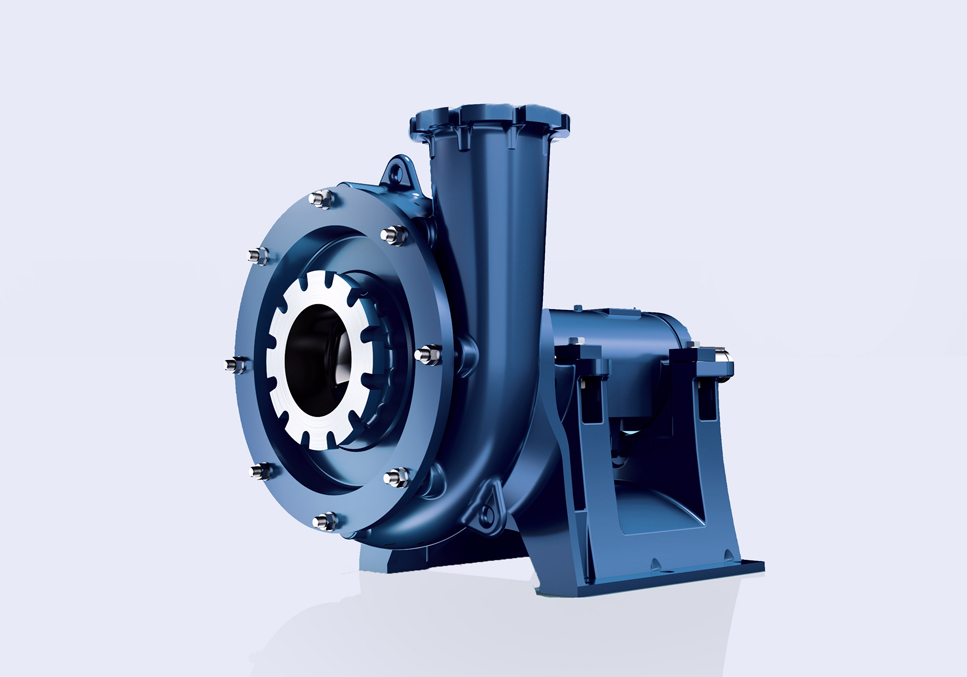

Reliability pays off when it comes to the GIW® LCC Pump series. GIW® LCC pumps are recommended for applications with coarse or fine particles—that includes anything from solids-laden waste to aggressive slurries of an abrasive and/or corrosive nature. LCC’s rugged design features, combined with shell, impeller and liner in our proprietary Gasite® material, are recognized worldwide for superior abrasion resistance. Additionally, several impeller options are available to fine tune pump performance to meet your operating needs. These options allow for optimum wear life and sustained efficiency.

To achieve high performance and low maintenance, the wet end is comprised of three components: a shell or casing, an impeller that screws onto the shaft, and a suction plate/liner to permit easy assembly and disassembly for maintenance and inspections.

The LCC range consists of three models: LCC-M (metal), LCC-R (rubber), and LCC-H (heavy). LCC pumps have a maximum allowable working pressure (MAWP) up to 16 bar.

The LCC is suited for a number of applications that include:

LCC Quick Ship 2.0 There are 105 LCC pump series offerings to choose from including the throat brushing (TB) shaft seal, low flow lantern ring (KE) shaft seal, and expeller shaft seal. The LCC-M is equipped with a Gasite® 28G high chrome white iron impeller, suction liner, and casing. The LCC-R has a natural gum rubber liner or Gasite® 28G high chrome white iron impeller. To see the full list of offerings and begin the quotation process, visit the Quick Ship website.

|

||||

-

Programs

- Contact Us

- About Us

KSB Mining – Your Solution for Slurry and Non-Slurry Centrifugal Pumps.

As one of the world’s leading manufacturers of centrifugal pumps and valves, the KSB Group is proud to be the single-source for all of your pumping needs. Through the KSB Mining division, we focus resources on your industry, concentrating our leading expertise on centrifugal pumps in slurry and non-slurry applications in mining and dredging operations.

Solving Your Mining Challenges

We understand your production concerns. Top mining companies turn to us because we collaborate with them to deliver solutions that improve efficiency, increase safety and help them achieve their mining sustainability targets. We engineer our pumps and IIoT solutions to increase production while reducing power requirements, emissions, and water use.

We are dedicated to continuous product improvement. Our R&D facilities include a world-renown, full-scale Hydraulic Lab equipped for testing pump performance and optimizing slurry systems. This state-of-the art laboratory is where our experts develop new pump technologies and IIot features for your unique requirements.

GIW® Slurry Pumps

KSB supplies a comprehensive range of products for slurry transport. Our line of GIW® slurry pumps are designed to move slurry efficiently across various applications in the hard rock mining, mineral mining, oil sands and dredging industries. Our portfolio of mining products includes cyclone feed and other screen pumps, slurry pumps, and process pumps. GIW® slurry pumps are also used in hydrotransport applications and long-distance tailings disposal.

When it comes to slurry transport, we provide precisely what our customers need: rugged, cost-effective slurry and mining pumps. KSB’s innovative solutions help you maximize productivity while minimizing costs.

Choose GIW® pumps to extend runtimes, minimize unplanned outages and lower your total cost of ownership.

Global Support for Pumping Worldwide

Our global network reaches more than 100 countries. We have sales offices and Service Centers near you that provide comprehensive pump packages and technical consultancy support for hard rock and industrial mineral applications.

- Continuous support with selection, installation, startup, upgrades, and repairs

- Local spare parts inventory

- Assistance with supply chain management

GIW® LCC provides high efficiency, low maintenance and low total cost of ownership.

GIW® LCC provides high efficiency, low maintenance and low total cost of ownership.  The GIW® LCC pump series comes in a variety of sizes and specifications to fit your needs.

The GIW® LCC pump series comes in a variety of sizes and specifications to fit your needs.  The GIW® LCC pump is optimized for abrasive & corrosive applications.

The GIW® LCC pump is optimized for abrasive & corrosive applications.  Quick Ship 2.0 makes it possible to receive up to 2 LCC pumps and spare parts fast.

Quick Ship 2.0 makes it possible to receive up to 2 LCC pumps and spare parts fast.