|

Martin Engineering

|

||||

| Name: Rick Felde Phone: 541-549-1359 |

|

||||

|

|

|||||

|

|

|||||

| Martin Engineering Features Bulk Material Handling Technologies at ConExpo-Con/Agg 2023

The global leader in bulk material handling will feature a wide range of technologies at ConExpo-Con/Agg 2023 to help customers achieve cleaner, safer and more productive operations. With more than 75 years in business and facilities in 16 countries to deliver products and services virtually anywhere in the world, Martin Engineering continuously develops innovative solutions to common problems and provides expert training to maximize efficiency and minimize risk. Keeping It Clean One family of Martin’s high-performance conveyor belt cleaners has been designed with an innovative method of holding the urethane blade in place without the need to mill any slots for holding pins. The QC1+™ Belt Cleaners from Martin Engineering can be cut to length to fit virtually any application, reducing the need for customers to stock multiple blade sizes to accommodate different belt widths. Operators simply trim the blade to the desired size from the stock 9-foot (2.74 meter) length to match the material path, slide in the blade holders and lock them in position. The new blade can be retrofitted to virtually any Martin main frame and most competing designs. Six different urethane formulations are currently available for the QC1+ series of products:

The company has also introduced its acclaimed CleanScrape® Cleaner, a revolutionary technology that delivers outstanding cleaning performance while virtually eliminating tensioning and maintenance after initial installation. The unique design from Martin Engineering features low belt wear, extended service life, reduced maintenance and improved safety, and ultimately a lower cost of ownership. With a service life up to 5x longer than traditional urethane designs, the system has proven so effective that it received the Australian Bulk Handling Award in the “Innovative Technology” category for its design and benefits. Unlike conventional belt cleaners that are mounted at a 90 degree angle to the belt, the CleanScrape Cleaner is installed diagonally across the discharge pulley, forming a three-dimensional curve beneath the discharge area that conforms to the pulley’s shape. The exclusive design incorporates a matrix of tungsten carbide scrapers and is tensioned lightly against the belt to prevent damage to the belt or splices. Despite extremely low contact pressure between belt and cleaner, it has been shown to remove as much as 95% of potential carryback material. The novel approach has been so effective that in many operations, previously crucial secondary belt cleaners have become unnecessary, saving further on belt cleaning costs and maintenance time.

Remote Monitoring With approximately 1000 operating systems currently in service and installations continuing daily, the technology has been embraced by bulk material handlers in a wide range of industries and applications. Designed in-house by the engineering team at Martin’s Center for Innovation (CFI), the N2 Position Indicator is produced solely in company-owned facilities to ensure the highest standards for quality control. In fact, the firm also engineered and built the proprietary equipment used to manufacture the new devices. Martin offers the PI, monitoring service and batteries free of charge to qualifying customers. The company will also support the components and provide customer alerts without cost as needed, with mainframes and tensioners replaced free as needed for users of Martin belt cleaner blades.

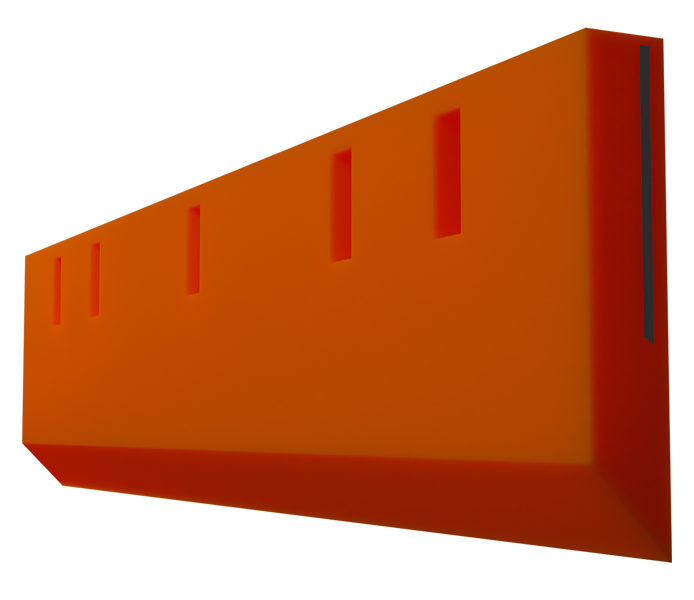

Maintaining Material Flow Material build-up is a common problem in aggregates processing. Slight changes in moisture content or other physical properties can cause adhesion to chutes or vessel walls, especially if the material is stagnant for any period of time. Martin Air Cannons have proven to be an essential part of aggregate processing and handling to promote the consistent movement of bulk materials, helping to prevent poor flow and blockages that can put a stranglehold on a plant’s profitability. Martin pioneered low-pressure air cannons for bulk handling applications in the 1970s with its first patented designs, and the firm has continued to develop new innovations in design, installation and function. Today, design and engineering advancements are producing air cannons that are lighter and more compact, with greater efficiency and power. Martin Engineering is continuously innovating the way they’re built, installed, serviced and powered in order to maximize production and reduce both downtime and the overall cost of operation, while contributing to improved safety. Conveyor Belt Sealing A key element in belt sealing is the wear liner, which absorbs the punishment of the bulk material load and serves as an attachment point for the skirt seal that rides atop the belt. Now there’s a new standard in wear liner technology. The Martin® Manufactured Canoe Liner is made from durable urethane molded around a rugged steel plate to absorb impact and abrasion from the punishing bulk handling environment. With the protective plate integrated directly into the urethane liner, the design delivers superior shielding of the skirt sealing system and chute wall from heavy, fast-moving cargo. The result is extended equipment life, longer periods of dust and spillage control, improved safety and less maintenance, reducing the overall cost of operation. The unique approach avoids the bonding issues common to previous designs, preventing urethane separation from the plate that could damage the belt and enclosure. Each section has a series of 2 inch (51 mm) long bracket holes for vertical adjustment. The bottom “belt side” of the liner is cut to an optional 20º, 35º or 45º angle to maximize belt sealing and protect the softer material of the skirt seal from premature wear.

Essential Training Martin’s series of Foundations™ reference books is another internationally-recognized resource for safety, maintenance and operations training — with more than 22,000 print copies in circulation around the world. The 500+ page reference books are available in several languages and have been downloaded thousands of times as free PDFs from the Martin website, helping to educate customers on best practices to improve efficiency and minimize potential hazards so they can achieve cleaner, safer and more productive bulk material handling. The company has recently launched a comprehensive digital educational resource for conveyor operation and safety. The online Foundations™ Learning Center draws from the collective knowledge and expertise gathered over nearly 8 decades solving bulk handling challenges. Aimed at apprentice technicians and experienced engineers alike, the non-commercial information is offered at no charge and is accessible by computer, tablet, or smartphone. An extension of the Foundations training curriculum, the Learning Center uses a mix of text, photos, videos, webinars, online events, and live experts available to answer questions. Specific modules cover material carryback and belt cleaning, fugitive material control, conveyor safety, belt and component damage, belt tracking, material flow issues and conveyor maintenance. The result is a unique central hub for industry professionals of all knowledge levels to use as a resource for building a deep understanding of material flow and safe, efficient conveyor operation. Martin Engineering has been a global innovator in the bulk material handling industry for more than 75 years, developing new solutions to common problems and participating in industry organizations to improve safety and productivity. Martin Engineering products, sales, service and training are available from 16 facilities worldwide, with wholly-owned business units in Australia, Brazil, China, Colombia, France, Germany, India, Indonesia, Italy, Mexico, Peru, Spain, South Africa, Turkey, the USA and UK. The firm employs more than 1,000 people, approximately 400 of whom hold advanced degrees. For more information, contact [email protected], visit www.martin-eng.com, or call (800) 544-2947. |

|||||

The QC1+ Belt Cleaners can be cut to length to suit virtually any application.

The QC1+ Belt Cleaners can be cut to length to suit virtually any application. CleanScrape forms a 3-D curve beneath the discharge area that conforms to the pulley’s shape.

CleanScrape forms a 3-D curve beneath the discharge area that conforms to the pulley’s shape. Employees and service technicians can quickly access info on any networked cleaner via mobile device.

Employees and service technicians can quickly access info on any networked cleaner via mobile device. Martin® Manufactured Canoe Liner with 45º trough angle and adjustable mounting height.

Martin® Manufactured Canoe Liner with 45º trough angle and adjustable mounting height.