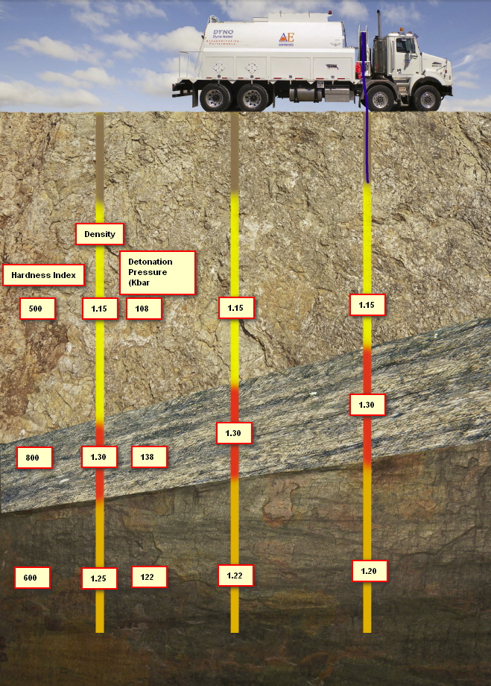

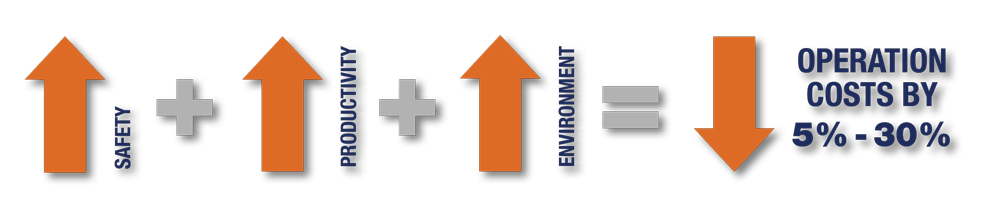

| What is DIFFERENTIAL ENERGY? A proprietary method for controlling the explosive energy profile in a borehole.  Watch the ΔE Explained Video here: https://youtu.be/49-mup32m_0 Improved Safety

Proven Success

Hear from our experts: https://youtu.be/1RUHa1ADRxE Learn more by visiting: https://www.dynonobel.com/practical-innovations/recent-innovation/deltae

|

-

Programs

- Contact Us

- About Us

Dyno Nobel is a global leader in the commercial explosives industry with over 3,770 employees, including some of the most highly trained blasters and technical experts in the industry. They manufacture over 54 million pounds of packaged explosives and over 1.2 million tons of ammonium nitrate with 32 manufacturing facilities on three continents (including state-of-the-art initiation systems facilities in the United States, Australia and Mexico). Their Engineering and Technology team support domestic and export product sales as well as the use of their cutting-edge technologies around the world.

Dyno Nobel has customers in the mining, quarry, construction, pipeline and geophysical exploration industries. The company operates in Australia, Canada, the United States, Africa, Indonesia, Mexico, South America, Papua New Guinea and Turkey. Dyno Nobel manufactures a full line of commercial explosives, including ammonium nitrate, bulk explosives, packaged emulsions, dynamite, detonators (electric, nonelectric and electronic), cast boosters, and detonating cord, as well as surface and underground loading systems and Portable Modular Emulsion Plants. They also offer services, including blast design, shot loading, shot service, vibration control, airblast, flyrock and NOx reduction, through DynoConsult, a specialist consulting division of Dyno Nobel.

Increased Productivity

Increased Productivity