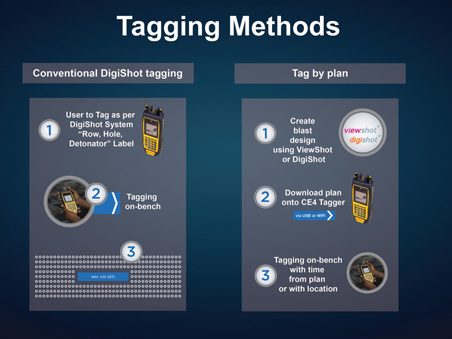

Safe. Simple. Smart. The new Ranger by Dyno Nobel is the ultimate DigiShot® blast initiation system designed with safety and performance at its core. Unique features such as end-of-line voltage validation, auto detonator detection, and flexible tagging maximize your productivity on the bench. The integrated RF Antenna delivers the durability and reliability you need. Ranger helps you optimize your time on the bench and at the blast.

Features

The Ranger has been completely redesigned for the open cut, quarry, civil, and construction industry. It has been vastly improved from the DigiShot 300 predecessor, providing twice the detonator capacity, updated weatherproof enclosure with a built-in antenna for longer range RF up to 3km, which makes it more robust for quick and easy deployment.

Electronic initiation is taking the future of mining to the next level. Electronic systems are more efficient and ensure consistent blasting results, every time. A reduced number of blasting delays, uniform rock fragmentation and uncompromised safety are only a few of the key factors that contribute towards sustainable mining.

|

|||||

-

Programs

- Contact Us

- About Us

Dyno Nobel is a global leader in the commercial explosives industry with over 3,770 employees, including some of the most highly trained blasters and technical experts in the industry. They manufacture over 54 million pounds of packaged explosives and over 1.2 million tons of ammonium nitrate with 32 manufacturing facilities on three continents (including state-of-the-art initiation systems facilities in the United States, Australia and Mexico). Their Engineering and Technology team support domestic and export product sales as well as the use of their cutting-edge technologies around the world.

Dyno Nobel has customers in the mining, quarry, construction, pipeline and geophysical exploration industries. The company operates in Australia, Canada, the United States, Africa, Indonesia, Mexico, South America, Papua New Guinea and Turkey. Dyno Nobel manufactures a full line of commercial explosives, including ammonium nitrate, bulk explosives, packaged emulsions, dynamite, detonators (electric, nonelectric and electronic), cast boosters, and detonating cord, as well as surface and underground loading systems and Portable Modular Emulsion Plants. They also offer services, including blast design, shot loading, shot service, vibration control, airblast, flyrock and NOx reduction, through DynoConsult, a specialist consulting division of Dyno Nobel.